Home » Cavitator

The Cavitator™ brand mud gas extractor

Our Cavitator™ brand Mud Gas Extraction Device is no ordinary mud agitator.

The motion of the Cavitator™ brand Mud Gas Extraction Device is so powerful it actually cavitates the mud by design, making it the world’s best at separating gas from drilling fluid also known as mud.

It is also very light, economical, very rugged, and resistant to getting bound up. The system runs on a safe Explosion Proof compressed air, 120 or 240 Explosion Proof AC. Custom models are available as well as stainless steel construction on special order.

Typically, the mud gas extractors employed today are an overly heavy construction, potentially unsafe, and are very hard to manipulate or adjust. The iBall Instruments Cavitator™ brand of mud gas extractor allows for the easy manipulation of adjustments, ease of service, and safety for the users and area.

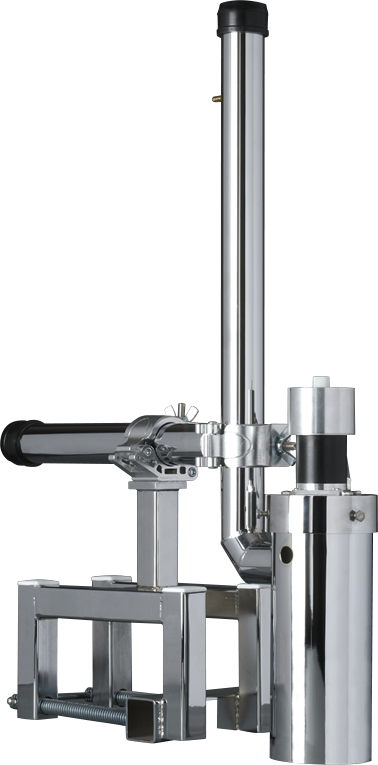

Using a common and easily adjustable 3 part platform that is attached to the drilling spoil separator various types of powered Cavitation motors.

The 3 part attachment platform is comprised of the Clamp assembly, Arm assembly and Barrel assembly.

The Clamp And Arm Assembly is comprised of heavy 13 gauge steel square and round tubing construction and deep chrome plated hardware. The 2 clasps are an industrial rated 2000 lb. wing nut adjustable assembly that allows for the extension or retraction of the Arm Assembly over the spoil separator.

The Barrel assembly is attached to the Arm assembly. The Barrel assembly also allows for the motor beater assembly to be attached easily to the top for ease of service and maintenance.

The Barrel assembly has an attachment at the top that allows for the extraction of the separated gasses from the drilling fluids (mud).

This design allows for the efficient extraction of drilling mud gasses and control of the sample collection chamber. This is an improvement over other extractors that act much as a centrifugal pump and spit drilling mud from the side. The long vertical tubing also acts as a condensation tower that helps eliminate much of the water vapor in the extracted sample.

The Cavitator also has a small diameter vent hole attached to the extraction chamber that allows for atmospheric pressure equalization.

This vent can be shielded from wind or blocked off completely for a difference in sample gasses extracted.

A simple and inexpensive rubber cap blocks the upper condensation tube opening. The upper tubing is fitted with a brass nipple where the sample extraction tubing is attached.

Clean up is easily facilitated by just removing the rubber cap and rinsing with pressurized water.

Rock cuttings do not pose an occlusion problem in the extraction tube because if any buildup accumulates above a certain point in the tubing it will just slide back down into the main chamber due to gravity. Sample extraction is enhanced by the Cavitator improved main chamber design. This also helps eliminate sample dilution.

The smaller design has also allowed this extraction system to attach directly to smaller shakers.

The motor beater assembly is a lightweight, high power motor assembly that is attached through a steel cap that attaches to the Barrel assembly. The shaft of any of the motors is attached to a balanced stainless steel custom fork assembly that is tested and can spin at over 4000 rpm.

The Motor beater assemblies come in 2 types depending on the setting and environment of the user.

Each type of motor type has its advantages.

The Air driven motor beater assembly can typically be driven with 10-50 PSI of air depending on the type of drilling fluid it is used in. It is protected from over pressure with a 60PSI pop off valve at the air motor assembly. This motor assembly is ATEX Certified as well as Class 1, Division 1 xplosion proof. It is classified as an oil-less motor, however, we also sell a water trap / in-line oiler and pressure regulator to go with it.

The Water trap has a built in water dump so that if water does collect in the line and trap, it will automatically be dumped when the float level inside reaches about an inch. Also, the regulator portion will keep the pressure nominal while the post oiler can maintain a mist of oil to the air motor beater assembly.

Includes explosion proof conduit box. The 120/240 volt AC motor assembly is utilized for more general installations at the shaker where low voltage solutions are not available. This motor assembly is ATEX Certified as well as Class 1, Division 1 explosion proof and built by the Marathon Motor Corporation.

The Cavitator brand mud gas extractor has been used worldwide by companies which include Baker Hughes, Horizon, Columbine, as well as numerous others.

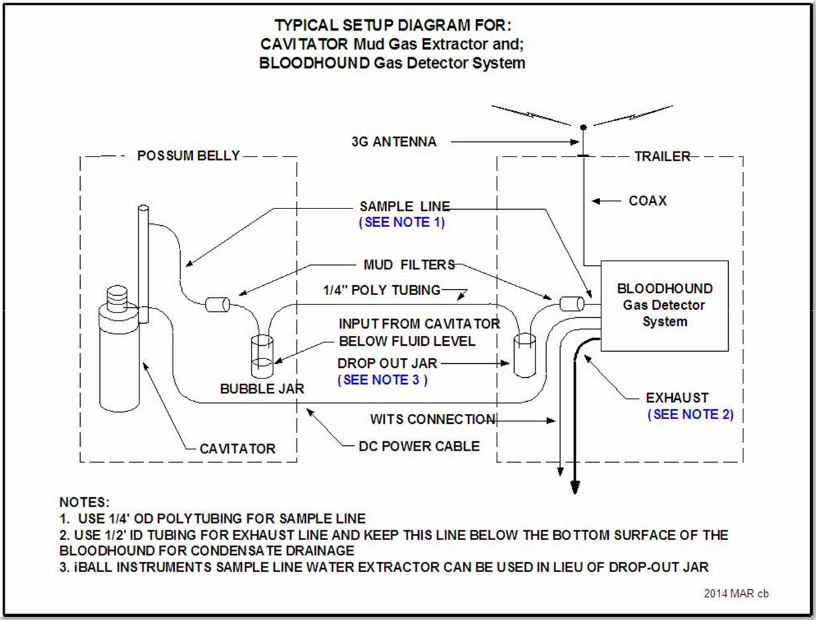

The Cavitator brand of mud gas extractor allows for very easy setup and maintenance and can be set up in as little as 10 minutes according to the following diagram.