Home » Bloodhound

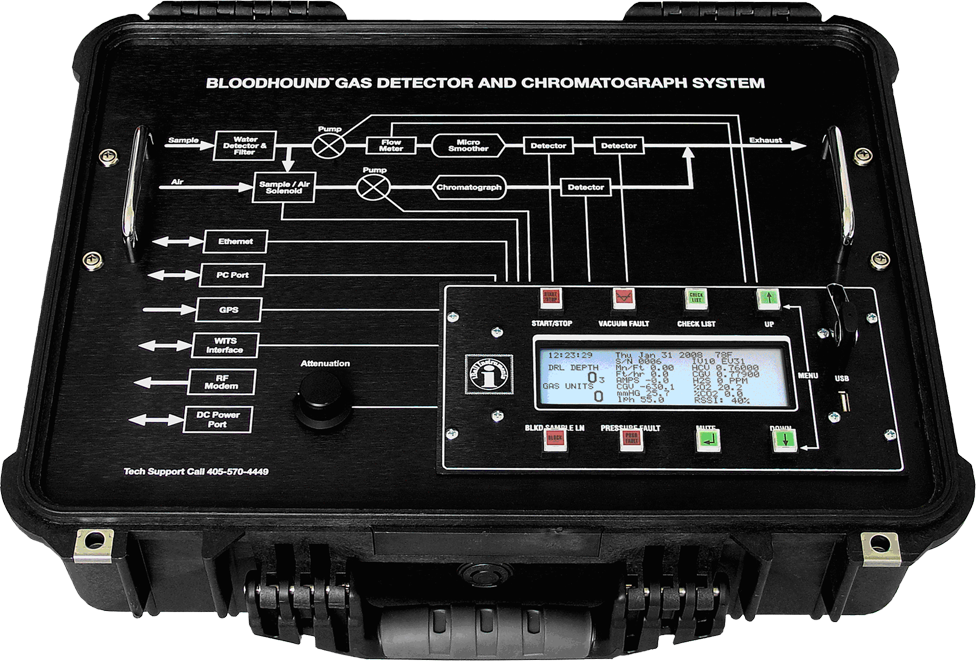

The Bloodhound® brand natural gas detector and chromatograph system

Our flagship product, the Bloodhound® gas detection and logging system is based on patented next generation infrared sensors that are light years ahead of the older hotwire, FID or Pellister based gas sensors. No other mud logging gas detection system uses this technology that makes it possible to create a system without peer in sensitivity, precision chromatography, reliability, portability, ruggedness, accuracy, and ease of use.

Ethernet RJ-45 to Internet

Analog out relay contacts for depth and alarms

Positive pressure vent air supply. Inside case under positive pressure with filtered air.

GPRS radio antenna

Audio Alarm

DC power in/out. Runs from DC car adapters or powers DC devices.

Universal AC power from 90-250VAC power and 45-65Hz

USB-B PC Connection

Pason compatible RS422 WITS interface

RS232 WITS Connection

RS232 Personal Computer External Data logger

Geolograph switch input

Simple gas inlet. Port has regulated flow and vacuum pressure.

Exhaust port 1/2 size keeps the line from freezing in cold weather.

The Bloodhound® can interface with WITS equipped drilling rigs to log all other drilling operations data along with collected gas sample data. Both WITS and sample gas data can be encrypted and sent through the internet to our secure servers via ethernet or the on board 4G cellular card. Authorized users can log into our secure Multiview web site and view the status of dozens of drilling operations in near real time, or view more detailed information and gas charts on any selected drill site with just a few mouse clicks.

The system can be configured to send a text message if something goes wrong like a clogged gas sample line or loss of power.

In addition to identifying the hydrocarbons coming in from the sample line, the Bloodhound® can also identify and measure Oxygen, Carbon Dioxide, and Hydrogen Sulfide.

Infrared Gas Detection and Hydrocarbon Analyzer System

Data

Automation

Communication

Power

Monitoring